Welding & Plasma Cutting Power Source

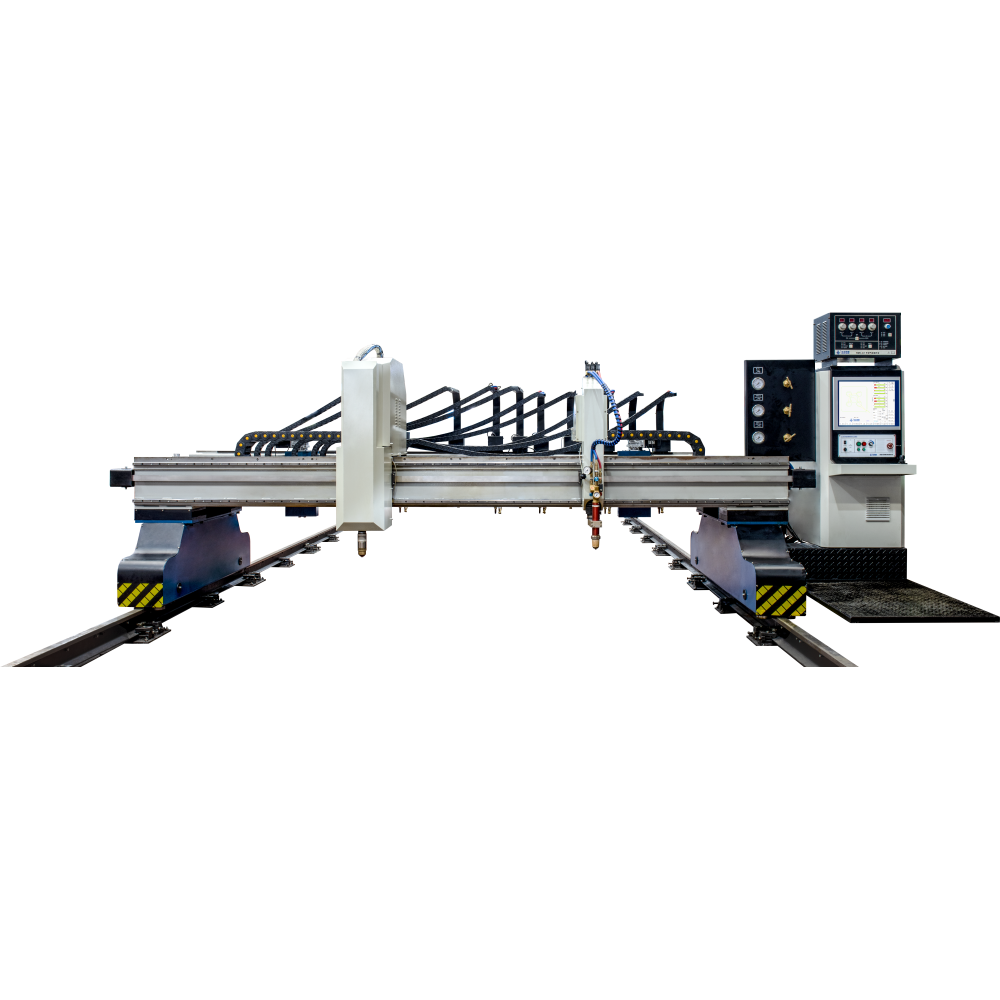

Automatic Welding & Cutting Equipment

Tel锛?086-28-85744099 锛圗xt 853)

Email锛歨wayuansales@163.com hy_sales@126.com

Address锛?299 Konggang 2th Road, Shuangliu Southwest Airport Economic Development Zone, Chengdu City, Sichuan Province

Wechat official account

Alibaba store